Machining & Routing

© 2015 Angeles Composite Technologies, Inc. • 2138 W. 18th Street • Port Angeles, WA • 360-452-6776

Facility Layout

ACTI resides in a 100,000 sq.ft, facility built for aerospace manufacturing with approximately 11,000 sq.ft. of clean room space and approximately 1,100 sq.ft. for a controlled environment test laboratory.

ACTI has received all necessary approvals for an additional 140,000

sq. ft. of facilities to be added to the campus.

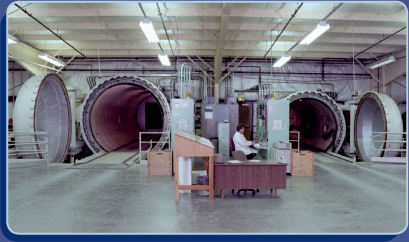

Autoclaves

ACTI operates and maintains two Thermal Equipment autoclaves. T1 is 10 feet in diameter and 40 feet long. It is capable of sustaining 850 degrees Fahrenheit at 250 PSI. T2 is 8 feet in diameter and 30 feet long. It is capable of sustaining 800 degrees Fahrenheit at 200 PSI. Both autoclaves utilize control software with both computerized and manual backup systems. All instruments are calibrated and traceable to NIST standards. Back To Top

AUTOCLAVE T1

10X40, 250 PSI, 850 DEG. F.

AUTOCLAVE T2

8X30, 200 PSI, 800 DEG. F.

AUTOCLAVE T1

10X40, 250 PSI, 850 DEG. F.

AUTOCLAVE T2

8X30, 200 PSI, 800 DEG. F.

(Click on photos for a larger version and description)

Today, ACTI operates and maintains one Thermwood 5 axis router. Overall part size envelope is 120”X x 60”Y x 36”Z.

Along with the 5 axis router, we operate a 3-Axis Manual Bridgeport Milling Machine.

ACTI also uses two Gerber CNC kit cutting machines to prepare the company’s material kits.

And we have a Virtek laser ply projector

Back to Top

Today, ACTI operates and maintains one Thermwood 5 axis router. Overall part size envelope is 120”X x 60”Y x 36”Z.

Along with the 5 axis router, we operate a 3-Axis Manual Bridgeport Milling Machine.

ACTI also uses two Gerber CNC kit cutting machines to prepare the company’s material kits.

And we have a Virtek laser ply projector

Back to Top

Test Equipment

(Click on Photos for a larger version and description)

ACTI’s laboratory is outfitted for the physical and mechanical testing of composite materials and completed structures. ACTI has the equipment, facilities and expertise to perform physical analysis of composite materials for properties such as, but not limited to, Resin/Volatile Content, Gel Time, Flow characteristics and Flammability.

ACTI’s mechanical test center is equipped with a +/-50 kN or +/-5 kN load cell. ACTI uses precision test fixtures built by Wyoming Test Fixtures to strict ASTM standards or specialized fixtures built to customer drawings/specifications. ACTI utilizes industry standard measuring equipment, calibrated to NIST traceable standards, to control the dimensional accuracy of parts and equipment.

Back To Top

ACTI’s laboratory is outfitted for the physical and mechanical testing of composite materials and completed structures. ACTI has the equipment, facilities and expertise to perform physical analysis of composite materials for properties such as, but not limited to, Resin/Volatile Content, Gel Time, Flow characteristics and Flammability.

ACTI’s mechanical test center is equipped with a +/-50 kN or +/-5 kN load cell. ACTI uses precision test fixtures built by Wyoming Test Fixtures to strict ASTM standards or specialized fixtures built to customer drawings/specifications. ACTI utilizes industry standard measuring equipment, calibrated to NIST traceable standards, to control the dimensional accuracy of parts and equipment.

Back To Top

Ovens

(Click on photos for a larger version and description)

ACTI operates and maintains one Michigan Oven Company oven and one Lewco oven.

OVEN #1

MICHIGAN OVEN COMPANY – 6FT X 6FT X 6FT

OVEN #2

HEAT PRO OVEN BY LEWCO – 10FT X 10FT X 10FT

Back to Top

ACTI operates and maintains one Michigan Oven Company oven and one Lewco oven.

OVEN #1

MICHIGAN OVEN COMPANY – 6FT X 6FT X 6FT

OVEN #2

HEAT PRO OVEN BY LEWCO – 10FT X 10FT X 10FT

Back to Top

Storage

ACTI maintains 1,500 sq.ft of controlled-access storage

for raw materials.

FREEZER #1

POLAR PANELS, 10FTX12FTX8FT, -5 DEG. F.

FREEZER #2

POLAR PANELS, 15FTX30FTX8FT, -10 DEG. F

Back To Top

for raw materials.

FREEZER #1

POLAR PANELS, 10FTX12FTX8FT, -5 DEG. F.

FREEZER #2

POLAR PANELS, 15FTX30FTX8FT, -10 DEG. F

Back To Top

Facility Photos

(Click on photos below for a larger version

& description)

& description)

Fly to:

Main Photo above of Bombardier Q400 Aircraft - By Bombardier Aerospace